Renovación de las torres de refrigeración de la central eléctrica de Didcot

Didcot Power Station contacted our SPX Cooling EMEA team to refurbish a 31-cell cooling tower system originally supplied by Bulk Order, a legacy brand of SPX Cooling.

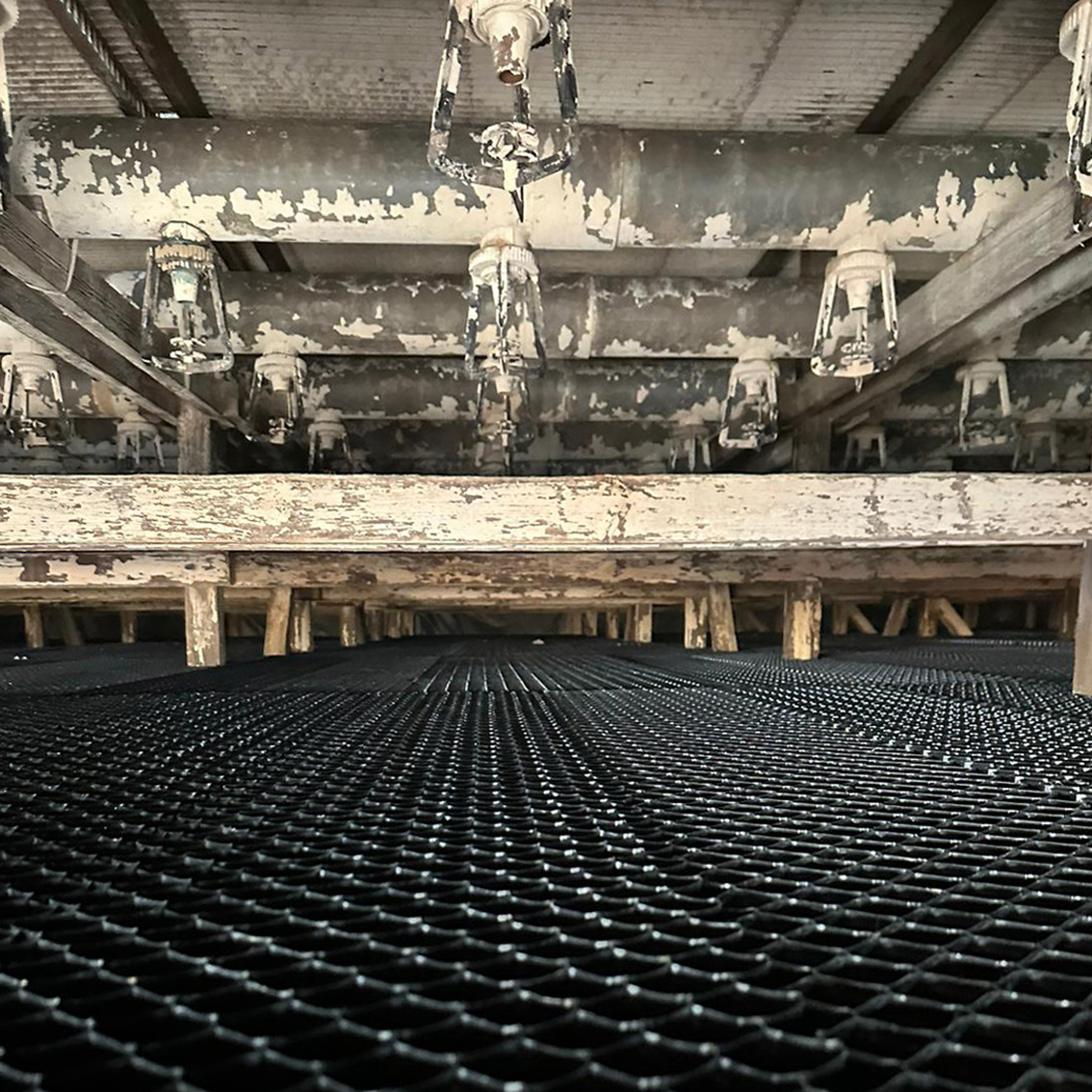

Over time, the timber structure and fill packs of these parallel-path wet and dry cooling towers (PPWD) had deteriorated, requiring extensive maintenance to ensure operational efficiency and structural integrity.

The refurbishment project would require us to replace heavily fouled PVC fill packs, restore the timber structure, and enhance safety and performance, all while minimizing disruption to the station’s ongoing operations. This was a large-scale project executed over multiple orders due to its complexity and duration.

The entire project was conducted under CDM (Construction Design and Management) regulations, ensuring adherence to rigorous safety and compliance standards.

- Water Conservation: The cooling tower’s live pond necessitated innovative solutions to safely access and perform maintenance without contaminating the water.

- Safety and Logistics: With over 100 lorry loads of materials transported on and off-site, and personnel working at height and in confined spaces, safety was paramount.

- Weather Variability: The project spanned all seasons, with extreme heat, heavy rain, and cold temperatures, each posing unique challenges.

- Aging Infrastructure: The original structure required meticulous inspection and selective replacement of timber elements to ensure long-term durability.

1. Safety-First Approach:

The SPX Cooling team designed horizontal access by removing cladding sheets, enabling safe entry over the live pond. Our crew installed youngman boards and reinforced scaffolding with metal handrails to create stable work platforms. All the while, we ensured all personnel were harnessed and clipped in during operations at height.

2. Phased Execution:

The cooling towers were refurbished on a cell-by-cell basis, minimizing downtime and ensuring continuous operation of the unaffected cells. Crews removed fouled fill packs and transported them off-site for proper disposal using bulker lorries.

3. Structural and Performance Enhancements:

Onsite teams replaced key structural components, including posts, horizontals, diagonals, and partition walls, to restore integrity. Once completed, we installed new PVC fill packs, wind baffles, and deflector boards to improve cooling efficiency and reduce structural strain. The team also inspected and optimized nozzle distribution systems for better performance.

4. Collaborative Problem-Solving:

Worked closely with the client to identify and implement alternative methods that improved safety and efficiency. Regular communication ensured alignment on goals and adjustments. The customer’s supportive and collaborative approach was instrumental in the project’s success. By fostering an open dialogue, they enabled us to explore and implement innovative solutions, balancing flexibility with a focus on safety and quality. Their willingness to engage with our recommendations and adapt to new methods greatly enhanced the efficiency and outcomes of the refurbishment.

1. Safety-First Approach:

The SPX Cooling team designed horizontal access by removing cladding sheets, enabling safe entry over the live pond. Our crew installed youngman boards and reinforced scaffolding with metal handrails to create stable work platforms. All the while, we ensured all personnel were harnessed and clipped in during operations at height.

2. Phased Execution:

The cooling towers were refurbished on a cell-by-cell basis, minimizing downtime and ensuring continuous operation of the unaffected cells. Crews removed fouled fill packs and transported them off-site for proper disposal using bulker lorries.

3. Structural and Performance Enhancements:

Onsite teams replaced key structural components, including posts, horizontals, diagonals, and partition walls, to restore integrity. Once completed, we installed new PVC fill packs, wind baffles, and deflector boards to improve cooling efficiency and reduce structural strain. The team also inspected and optimized nozzle distribution systems for better performance.

4. Collaborative Problem-Solving:

Worked closely with the client to identify and implement alternative methods that improved safety and efficiency. Regular communication ensured alignment on goals and adjustments. The customer’s supportive and collaborative approach was instrumental in the project’s success. By fostering an open dialogue, they enabled us to explore and implement innovative solutions, balancing flexibility with a focus on safety and quality. Their willingness to engage with our recommendations and adapt to new methods greatly enhanced the efficiency and outcomes of the refurbishment.

- Improved Efficiency: The new fill packs significantly enhanced the cooling tower’s efficiency, ensuring optimal performance.

- Extended Lifecycle: Structural replacements and enhancements have extended the operational life of the cooling towers.

- Zero Safety Incidents: Despite the project’s complexity, it was completed without any lost-time incidents, underscoring our commitment to safety.

- Client Satisfaction: The client praised our team’s professionalism, flexibility, and adherence to high safety standards, stating, “If all of our contractors worked like SPX, our lives would be much easier.”

La renovación de las torres de refrigeración de la central eléctrica de Didcot demuestra nuestra experiencia en la gestión de proyectos complejos a gran escala con precisión y seguridad.

By combining legacy knowledge with innovative solutions, we delivered a project that met and exceeded the client’s expectations, reinforcing the SPX Cooling EMEA reputation as leaders in cooling tower refurbishment.

Nuestros clientes hablan: escuche lo que dicen:

"Marley fue la marca con la que aprendí todo sobre torres de refrigeración. A día de hoy, seguimos utilizando Cooling Tower Fundamentals como guía de referencia para los nuevos ingenieros que se incorporan."