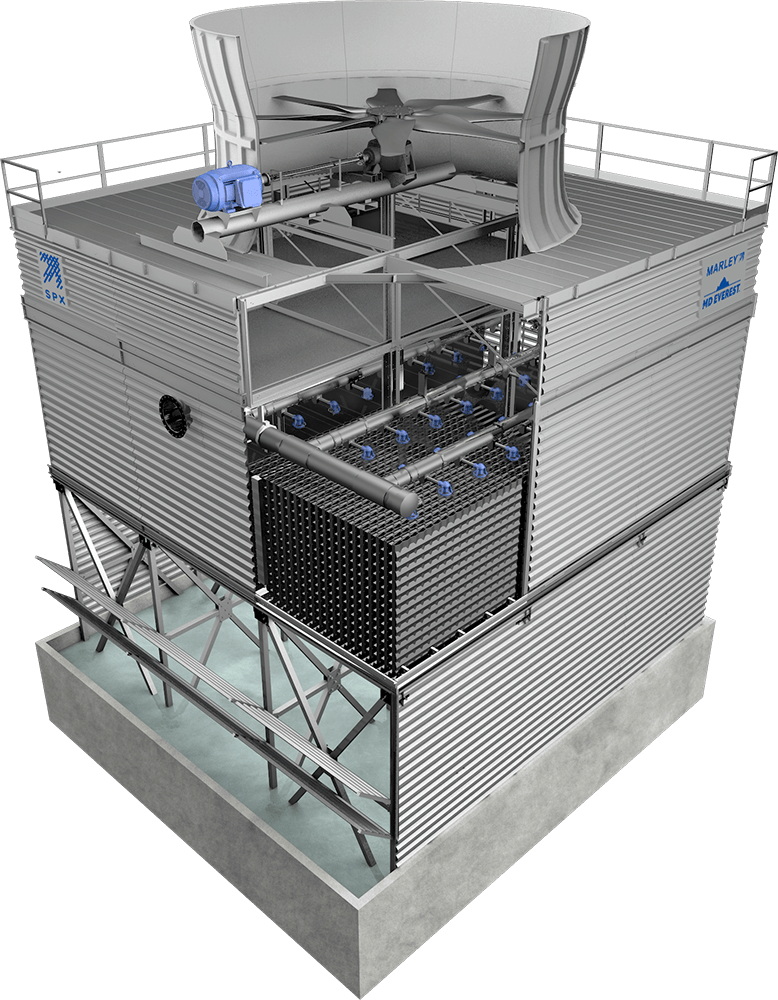

Marley MD Everest

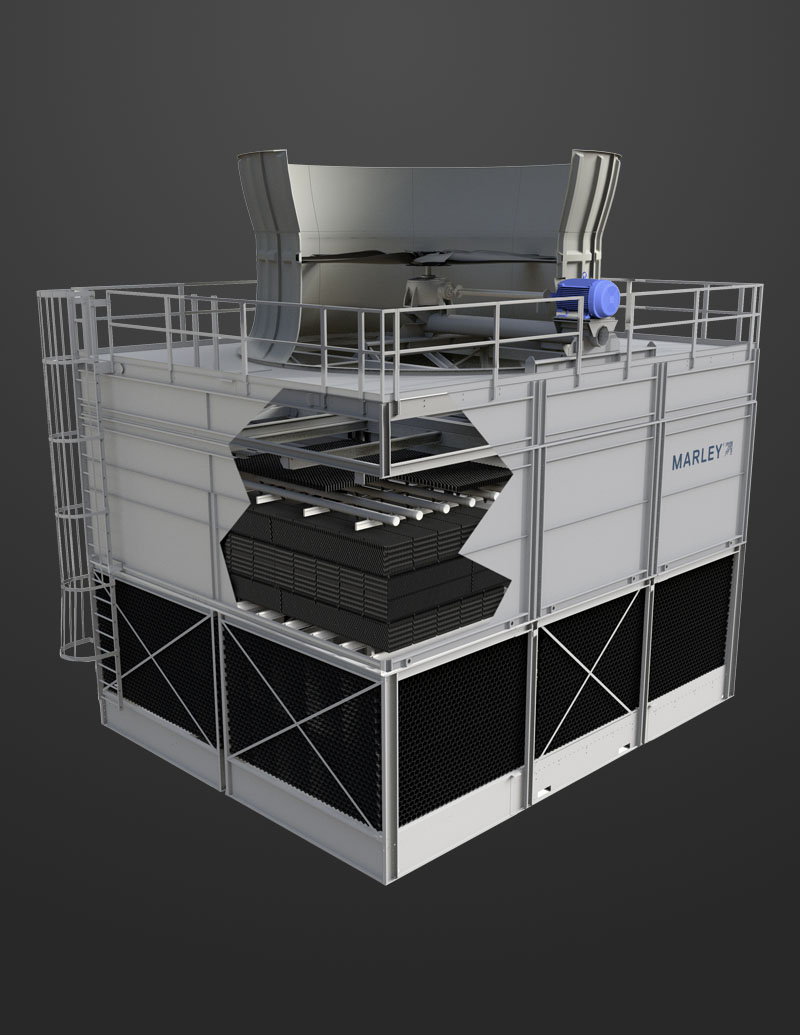

When SPX Cooling Technologies engineers began their quest to design a new counterflow cooling tower, they were challenged to reach new heights in cooling performance. Also required was a tower design that would simplify and speed factory fabrication, delivery and field assembly.

Details and Features

The MD Everest Cooling Tower is uniquely suited for applications with higher cooling demands, including data centers, district energy complexes, health science campuses and industrial complexes. It incorporates robust materials of construction and industrial-grade components, proven to withstand the rigors of harsh environmental exposure. And its unique design comprises preassembled modules with fewer components, delivers to the job site up to 60% sooner and installs up to 80% faster than field-erected cooling towers.

HVAC and Process Cooling Applications:

Compared to other preassembled counterflow cooling towers, the MD Everest Cooling Tower offers monumental advantages for HVAC and Process Cooling applications:

- Up to 58% more cooling capacity than other preassembled cooling towers

- Cooling capacities from 1227-3790 tons offer one-to-one matches for large chillers

- Fewer piping and electrical connections reduce installation costs

- Low drift rates, down to 0.0005 percent of circulating water flow

Process Cooling Applications:

Compared to field-erected towers, the MD Everest Cooling Tower offers sky-high advantages for Process Cooling applications:

- Industrial-strength construction and materials to meet the rigors of process cooling applications

- Maximum flow rate up to 12,602 gpm/cell (2862m3/hr) to meet demands of process cooling

- Modular design for consistent quality and safer assembly processes and shorter work duration

- Broad range of heat transfer fill types to accommodate varying water quality

- Scalable design based on project requirements

The MD Everest Cooling Tower rises above the rest with unmatched cooling capacity, energy efficiency, fewer components and lower maintenance costs. Additional advantages that distinguish it as a member of the Marley MD Cooling Tower product line:

Robust Design and Materials

- Structural design and materials meets seismic and wind load requirements

- 5-year maintenance-free System 5 Marley Geareducer® gear drive

- Low fan energy requirement

- Spray system evenly distributes water over the fill

- Energy-efficient PVC heat exchange fill media options

- Motor outside the airstream standard

- Fill protected from sunlight to discourage algae growth

Certified Thermal Performance

Certified by the Cooling Technology Institute to meet thermal performance as specified.

Our Customers Are Talking - Hear What They Have To Say:

I highly recommend SPX Marley for their outstanding performance and dedication."